Ready for the rollercoaster? It’s all my niece Kylie‘s fault, I blame her entirely ;)

For Christmas my niece Kylie asked for (and got) a Cricut. I think she was mostly excited about using it for designing and customizing with vinyl. It’s become so popular in the last few years that several of my online indie seller forums have become almost entirely Cricut related posts, and I knew it really has become a whole thing when the craft shops have expanded, and expanded, and expanded their Cricut offerings. I began to joke of the “Cricut Cult.”

I have long loved my Xacto knife. I know my way around a knife, and at my old newspaper job, they didn’t call me the Paste-up Queen for nothin’! My paper and knife cutting prowess evolved from career work into my personal art, as seen in my paper stencil stack collage pieces. As an artist I felt like “Why buy a whole machine to cut something that I could do by hand in a jif, and enjoy doing so!”

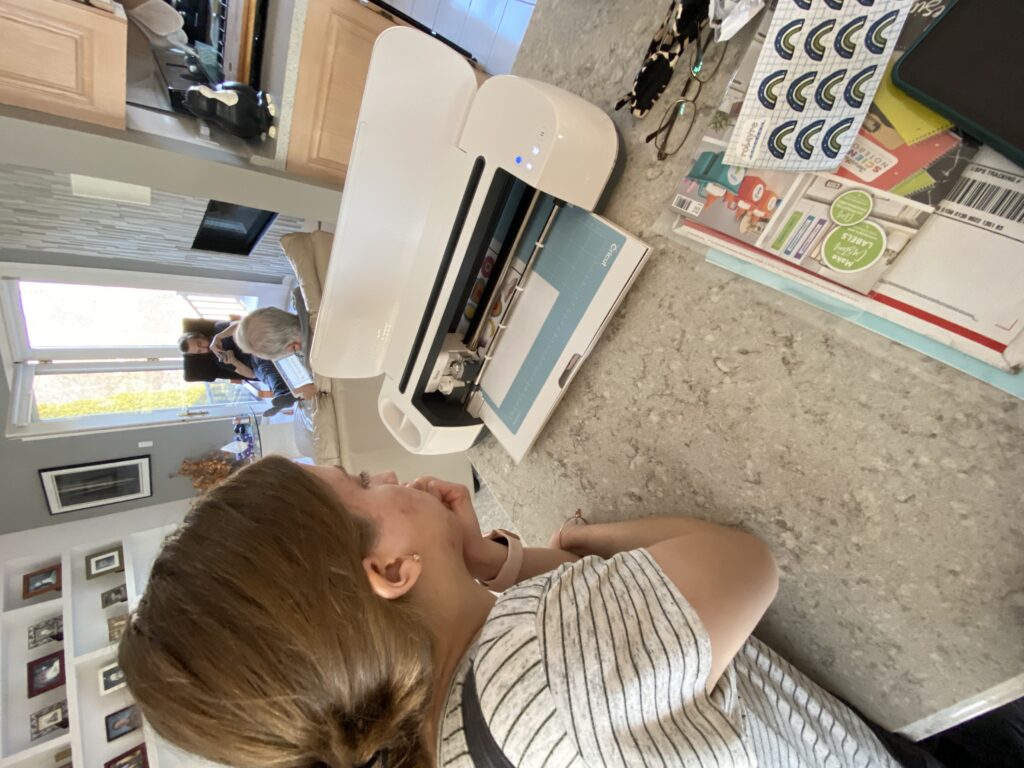

That being said, Kylie was EXCITED about her new toy. Knowing that I’m crafty, she said she was going to bring her Cricut out with her when she visited next and we could play around with it. We watched some youtube videos, and setting up her machine was easy-peasy. The next time we met up she said she was bringing it out again so we could explore some more with her machine, as she hadn’t really been able to on her own yet. I remembered some youtube videos I’d seen where people used their Cricuts to kiss-cut their own sticker sheet designs. As I had designed (and had printed professionally) a few of my own already, I thought it would be fun to do it all on my own. I binged tons of youtube Cricut sticker videos.

When Kylie and I met up, I brought my printer and some label sheets, she brought her Cricut and we did it, just like that. I had already designed a sticker sheet last year, so I quickly made an adjustment, repeating one of the most popular and requested rainbows, and made a new sheet design. We printed them out, cut them up and made our own stickers. Once again, easy peasy.

It was SO EASY that upon later reflection, it was probably too good to be true. But, I got kind of obsessed with watching more and more youtube videos on artists using Cricut for the business, and wanting to make and cut my own stickers, eliminating the middle man. I finally decided to push the go button and buy my own Cricut, something Me from 6 months ago would never have ever imagined. I felt like I was crossing over into the dark side.

I thought about my options and decided ordering it straight from the company, and supporting the original business was the best idea, rather than picking one up locally at a craft store, or ordering if off of Amazon, etc. This was probably my first mistake. If I had it to do over again, I’d definitely pick one up from Michael’s. I imagine the ones Michael’s has have traveled wrapped up on a palette with a whole bunch of them, as opposed to one single machine in a box, being rolled, dropped, kicked and tumbled from California to Illinois.

The first machine (spoiler alert, there’s more than one) couldn’t connect to bluetooth or wifi, and even when I wired it up, the registration wouldn’t work. There is a registration page you need to print out and calibrate the machine, and I probably printed and cut out dozens of sheets and no matter what I did, it was always off registration the exact same amount, it never readjusted, even if I put in really crazy far away numbers, it stayed exactly off registration where it had been. I contacted Cricut hoping that they might be able to do some sort of reboot and update that would fix it, but sadly they confirmed it was a hardware issue. I had to make a video recording the issues, running it through the same things IT support had me do and send it to them. They contacted me back, confirming that the issue was real and they would be replacing my machine. That first machine was then deactivated, and instead of sending me a label, they said to dispose of it however I like. They sent me another machine.

The second machine arrived and it was bad news right out of the box. The outside shipping box was fine, but the inner product box was torn open, as if someone had been too impatient to cut the tape and just ripped it open. Not a good sign. When I took the machine out for the first time I noticed dirt and smudges all over it, not a clean pristine looking new product. When I opened the machine, the placement of the feeder guides were all pushed together, rather than evenly spaced like on the first machine. Despite all of this, these are simple cosmetic issues and if the machine works than I would be fine with wiping it down and readjusting it. Unfortunately, when I turned on the machine it was very loud compared to the previous one, and made grinding and clunking sounds. When I tried to calibrate the machine, it tore the paper when it should be cutting, and the registration also didn’t seem to adjust. Later, I suspected that this second machine was probably also a lemon, and previously purchased and returned once before, and that someone put an old, used blade into it and kept the new one.

At this point I think I started crying. I’d made a mistake, I should never have gotten lured in by Cricut. What I didn’t mention above is that to call Cricut and get a hold of a customer representative is going to be at least an hour or two long hold before you even talk to someone, not just me, I’ve read other complaints about it online. With the second machine, I think I sat on hold for over an hour and when someone answered we were almost immediately disconnected, no call back, nothing. I had no other option than to call back again and sit on hold for another hour, then I think they put me on hold for a half hour, before finally talking with someone again. Each time, I’d have to explain everything all over again, and then go through all their steps, and then video record it all and upload it. This time they told me they’d send me a label to return it, but no label arrived, and when they finally deactivated the machine and released a new machine to me, they told me to just dispose of it myself as well.

After TWO bad machines, I was ready to just throw in the towel. If I hadn’t had to sit on hold for hours and hours, and forced to cool down, I would have insisted on a refund and moved on with my life. During this time I heard many praises about Silhouette… just sayin’.

They deactivated the second machine, and with a third Cricut on the way, I realized I might be starting to grow a Cricut graveyard.

Let’s be honest, when the third machine finally arrived I was drained. All excitement and enthusiasm for this product was long gone. It took me a day or two to even try it out. While the registration still wasn’t perfect (not like how I’d witnessed it with my niece Kylie’s machine), I just didn’t have any fight left it in me. It would have to be good enough. I wonder how many people have no idea the registration is off/broken just because they don’t need it to be spot on like one does when making sticker sheets.

You can see the grass stickers after being outside for a few months. The stickers are still there, but the image is a ghost of what it was originally. Meanwhile, the professionally printed Vinyl rainbow sticker is going pretty strong, well over a year later.

While waiting for my original machine to arrive, I had ordered some sticker paper (matte and glossy vinyl) and set up a new mini sticker sheet. Once the third machine arrived and I finally made myself use it, I had a hard time getting it to register AND cut the correct thickness, regardless of watching so many videos and trying so many different calipers of paper (washi, sticky note, label, etc.). It was not consistent. Some stickers on the same piece of paper might cut nicely, and others would get some that don’t cut all the way through, or cut the whole sticker out, rather than kiss cut the top away from the release paper. Then, despite the videos I watched, and product promises of weather proof vinyl sticker paper, the stickers I printed would smudge or bleed, but that is another issue for another day.

The machine sat on our coffee table now for two months, untouched until a couple weeks ago when I was preparing for a pop up event for the Art Skep group. I decided to make some stickers that were based on an oil painting I made from a cactus that came from the venue, The Sycamore Greenhouse. I used packing tape over the sticker paper, so that they would hopefully not bleed.

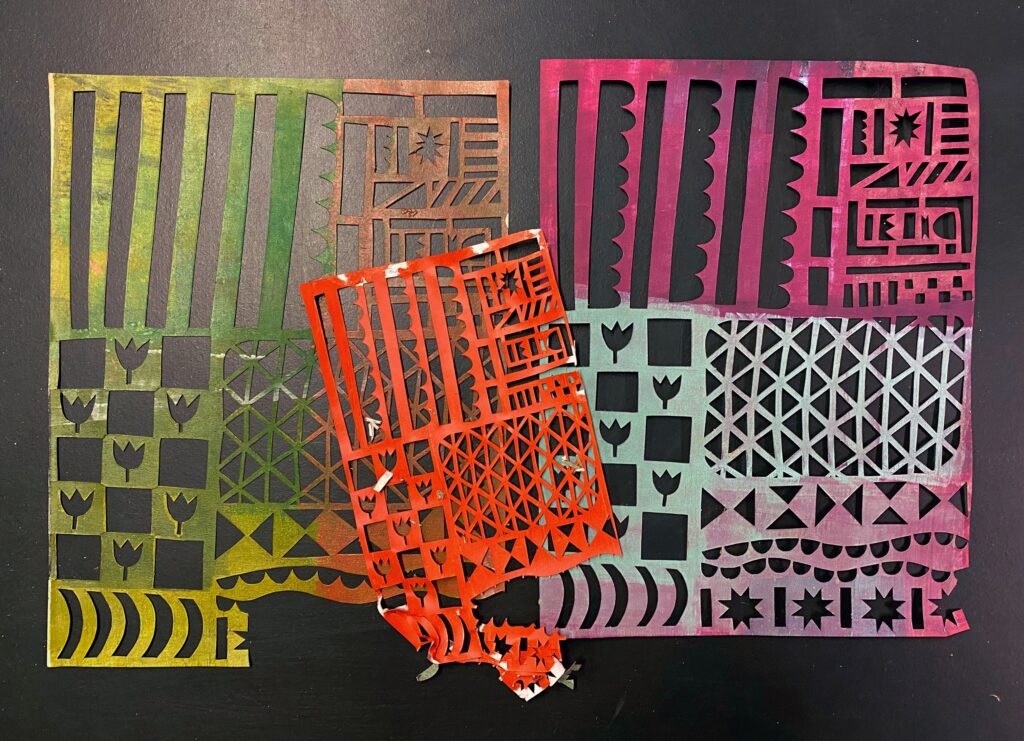

The left stencil was the original stencil I cut by hand, the one on the right is the one I made after scanning the original, cleaning it up and making edits. The top tiny one was an attempt to make a mini stencil. It would have worked fine if I hadn’t saturated the paper so much on the first print, and been impatient pull it up.

Then, last week while gelli printing, I was sad that one of my favorite, newer, hand-cut paper stencils tore. I had the idea to scan it, clean it up and then use my cricut to cut out another one. Part of me felt bad, because I do enjoy cutting stencils by hand with an Xacto knife. I tweaked the stencil, made some small improvements and cut it out, presto magic. THEN I had the idea that I could take that same stencil and reduce it by half to make the details even smaller, and replicate the stencil as a pattern, twice up on one 8.5×11. It worked out, and I was pleasantly surprised. It was easy enough that I may try my hand at designing some stencils for sale. I still see myself cutting stencils by hand, but this is definitely a way that I can reproduce them once they get torn, and built up with layers of paint.

Do I absolutely regret getting it? No, I guess not, but am I as excited about it as I would have been if I hadn’t had so much drama? You bet. I still don’t really use it as much as I would have liked, but I think (hope) that after a bit more time has passed, I might finally find a project that gets me really excited to use it and I can get over all of it. Also, I could see how learning Cricut would be a gateway into more techy type Maker stuff; 3D printers, laser cutting, etc.

robayre

Hi, I'm Robyn and I was Hatched from a Kinder Surprise Egg. Graphic Designer by day, Maker of things by night. I have worked as a graphic artist professionally since I was 16 years old. Went on to get my Bachelors of Art from NIU. I like to share my Artwork online at flickr.com/photos/robayre and on my own personal website http://www.robayre.com. I also have an online shop http://www.robayre.etsy.com where you can find more of my "crafty" sorts of things, as well as a random piece of artwork here and there. Oh, and I'm also an occasional contributor to Artomat (artomat.org).